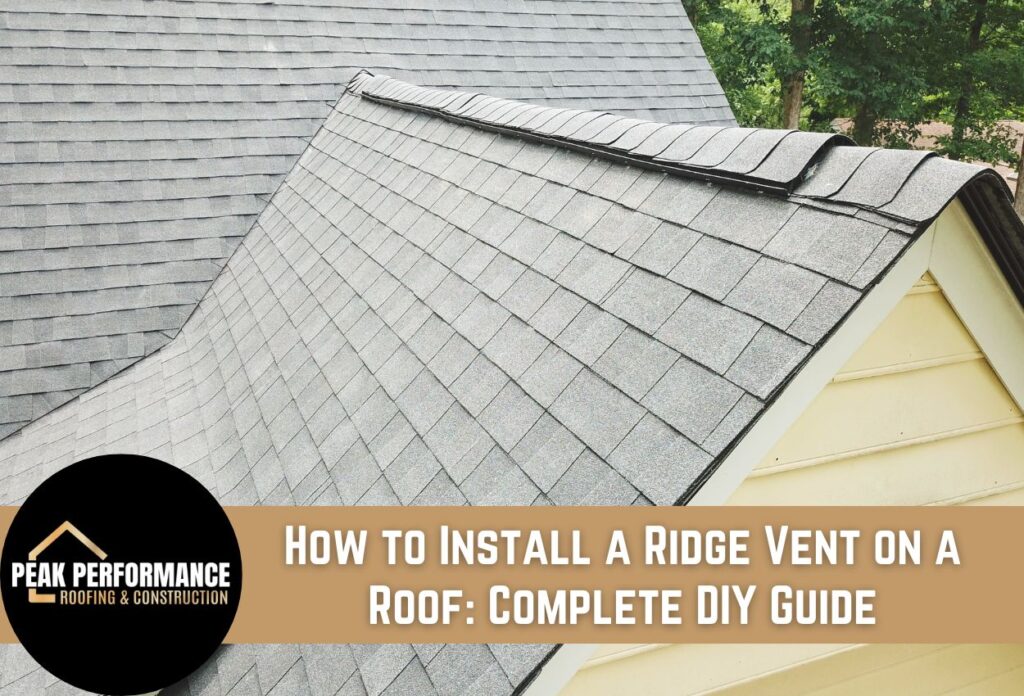

Attic ventilation is essential for maintaining your roof’s integrity and your home’s energy efficiency, especially in Tulsa’s varied climate conditions. Ridge vents are one of the most effective ventilation solutions available to homeowners today. These specialized vents run along the peak of your roof, creating a balanced airflow system that naturally draws hot, moist air out of your attic space while allowing fresh air to enter through soffit vents.

Installing a ridge vent on your roof has multiple advantages over traditional ventilation methods. By allowing continuous air movement, ridge vents help regulate temperature extremes, reduce moisture buildup, and prevent premature deterioration of roofing materials. For Tulsa homeowners, this means extended roof lifespan, improved energy efficiency, and reduced cooling costs during hot summer months.

The ridge vent installation process can be a manageable DIY project for those comfortable with roofing work and who take proper safety practices. However, it is usually best left to the professionals. With the right tools, materials, and step-by-step guidance, you can successfully install this roof vent. This improvement not only enhances your home’s performance but also adds value to your property by preventing common roofing issues.

Tools and Materials Needed for Ridge Vent Installation

Successful ridge vent installation requires having the right equipment on hand before you climb onto your roof. For Tulsa homeowners tackling this DIY ridge vent replacement project, preparation is key to completing the job efficiently and safely.

Tools for the installation process include a circular saw with a carbide-tipped blade for cutting through shingles and roof decking, a hammer or pneumatic nail gun for securing materials, roofing nails, a utility knife for trimming shingles, chalk line for marking straight cuts, pry bar for removing existing ridge caps, caulking gun with roofing cement, and measuring tape. Don’t overlook safety equipment: sturdy work gloves, safety glasses, knee pads, and proper fall protection are non-negotiable for roof work.

When selecting a ridge vent, consider Tulsa’s weather patterns. Look for models with external baffles that prevent wind-driven rain from entering while allowing proper roof ventilation. Shingle-over ridge vents are popular as they blend seamlessly with existing roofing materials. For metal roofs, specialized ridge cap ventilation systems are available. The vent should provide at least 18 square inches of net free area (NFA) per linear foot for optimal attic ventilation improvement. Local building codes may specify minimum ventilation requirements, so verify these before purchasing materials. The right ridge vent system will complement your specific roof pitch and design while standing up to Oklahoma’s weather extremes.

Preparing Your Roof for Ridge Vent Installation

Before beginning any ridge vent installation in Oklahoma, preparation is essential for both safety and successful results. Tulsa homeowners should carefully plan this project around weather conditions, as our region experiences everything from intense summer heat to winter storms. Early morning hours during spring or fall typically offer the most moderate temperatures for roof work. Always check the forecast and avoid working during rain, high winds, or when temperatures exceed 85 degrees Fahrenheit, as shingles become more susceptible to damage in extreme heat.

Safety must be your priority when undertaking roof ridge vent installation. Secure your ladder on level ground with proper anchoring, wear non-slip footwear, and use a safety harness when working on steeper pitches. Having a helper on the ground provides an extra layer of security during your attic ventilation improvement project.

Once safely on the roof, accurate measurement is crucial for proper roof ventilation techniques. Start by measuring the entire length of your ridge and subtract any areas that shouldn’t be vented, like intersecting ridge lines. Most experts recommend cutting a 2-inch wide opening, 1 inch on each side of the ridge, along the ridge line, leaving 6 inches uncut at each end of the roof for structural integrity. Use a chalk line to mark straight cutting lines parallel to the ridge. Being precise with this measurement ensures balanced airflow throughout your attic space while maintaining your roof’s structural integrity — an important consideration for homes in Tulsa.

Step-by-Step Ridge Vent Cutting Process

The most critical part of the ridge vent installation process is cutting the ventilation slot along your roof’s peak. This precise cut creates the pathway for hot, humid air to escape from your attic space. For Tulsa homeowners, getting this step right means better year-round ventilation performance, especially during our sweltering summer months.

Begin by carefully removing the cap shingles from the ridge using your pry bar. Work methodically along the entire length, saving undamaged pieces if possible. Using your chalk lines as guides, set your circular saw blade depth to cut through the sheathing but not into the rafters below (typically ¾ to 1 inch deep). Make parallel cuts along both sides of the ridge, maintaining a consistent 2-inch wide opening, 1 inch on each side of the center. Take your time with this step, as rushing can lead to uneven cuts and an unprofessional finish.

Watch for common mistakes that compromise your roof ventilation. Never cut across rafters or trusses, as this weakens your roof’s structure. Avoid cutting too wide a slot, which can allow water infiltration during Tulsa’s heavy rains. Uneven cutting creates gaps where the ridge vent won’t seal properly. Also, don’t extend cuts all the way to the roof edges — maintain that crucial 6-inch uncut section at each end to prevent weather intrusion. After cutting, carefully clear all debris from the slot and the surrounding area for sufficient airflow through the vent and to prevent future clogging.

Installing the Ridge Vent System

With preparation complete and ventilation slots cut, it’s time to install the actual ridge vent material. This critical step ensures your Tulsa home benefits from proper airflow while maintaining weather protection. Begin by unrolling the ridge vent material along the length of your roof ridge, centering it directly over the ventilation slot you’ve created. Most ridge vent products have alignment marks to help with positioning. Ensure the vent material extends the full length of the cut opening while maintaining the recommended 6-inch buffer at each end of the ridge.

Secure the ridge vent using roofing nails driven through the marked nail locations on the vent material. Place nails on both sides of the ridge, typically every 4 to 6 inches or according to manufacturer specifications. Be careful not to overdrive nails, as this can damage or distort the vent material. For homes in Tulsa’s storm-prone region, proper fastening is essential to prevent wind damage during severe weather.

When working with multiple sections of ridge vent, connecting them together correctly is crucial for a continuous ventilation system. Butt sections tightly together without overlapping, and apply a small bead of roofing cement at each junction to ensure a weathertight seal. For corners or transitions, follow the manufacturer’s instructions for cutting angles and sealing techniques. Once the entire ridge vent is installed and secured, apply the cap shingles over the ridge vent material. This provides a finished appearance while adding another layer of weather protection for your Tulsa home’s ventilation system.

Finishing with Ridge Cap Shingles

The final step in your ridge vent installation is properly securing the ridge cap shingles over your new vent. This critical phase ensures both the aesthetic finish of your roof and the long-term waterproof protection of your Tulsa home. Start at one end of the ridge and work toward the opposite end, placing each ridge cap shingle over the vent material with the appropriate overlap recommended by the manufacturer.

When nailing ridge cap shingles, use roofing nails long enough to penetrate through the vent material and at least 3/4 inch into the roof deck. Place two nails in each ridge cap, positioning them about an inch from each edge and making sure they’re covered by the next overlapping cap. Never nail through exposed areas, as this creates potential water entry points. Apply a small amount of roofing cement under the exposed edge of the final ridge cap to ensure a weather-tight seal.

Tulsa’s high winds require extra attention during ridge cap installation. Consider using six nails instead of four in high-wind areas, particularly on the north and west-facing sections of your roof. During hot weather installation, allow shingles to warm slightly before installing them over the ridge to prevent cracking. For enhanced wind resistance, some Tulsa contractors recommend specialized high-wind ridge cap shingles with reinforced construction. This extra protection helps maintain roof integrity during Oklahoma’s seasonal storms and ensures your new ridge vent system continues providing sufficient attic ventilation year-round.

Maintenance and Troubleshooting Your Ridge Vent

Even the best ridge vent installation requires regular maintenance to continue performing effectively through Oklahoma’s extreme weather conditions. For Tulsa homeowners, seasonal inspections are essential — aim to check your ridge vent system at least twice every year. During these inspections, clear any debris like leaves, twigs, or bird nests that may obstruct airflow. Examine the ridge vent material for cracks, warping, or separation from the roof surface that could compromise ventilation or allow water intrusion.

Watch for signs of inadequate airflow, which often shows as excessive attic heat in summer or moisture buildup in winter. If your attic remains significantly hotter than outside temperatures on summer days, your ridge vent may be clogged or improperly installed. Check that soffit vents remain unobstructed to maintain the continuous airflow path necessary for proper ventilation. Wildlife intrusion is another common issue in Oklahoma — small animals may damage or nest in ridge vents, particularly during colder months. Installing vent screens can deter pests while maintaining airflow.

For ridge vents showing signs of damage from Tulsa’s severe storms or hail, prompt repairs are crucial. Loose nails should be replaced with correctly sized roofing nails, and damaged sections of the ridge vent should be removed and replaced to maintain system integrity. Remember that a properly functioning ridge vents significantly extend your roof’s lifespan by preventing moisture-related problems and reducing heat buildup.

Trust Peak Performance Roofing & Construction for Your Roof Ventilation Needs

Installing a ridge vent on your roof is a significant step toward enhancing your home’s energy efficiency and protecting it from the harsh weather in Tulsa, OK. However, if DIY isn’t your strength or you’re unsure about the installation process, Peak Performance Roofing & Construction is here to help. With our expertise in proper roof ventilation techniques and ridge vent installation, we ensure your roofing project is executed flawlessly.

Don’t risk improper installation, which could lead to expensive roof damage. Call us today at (918) 694-1483 to schedule a consultation or to get professional assistance. Let us help you improve your attic ventilation with guaranteed quality and durability.