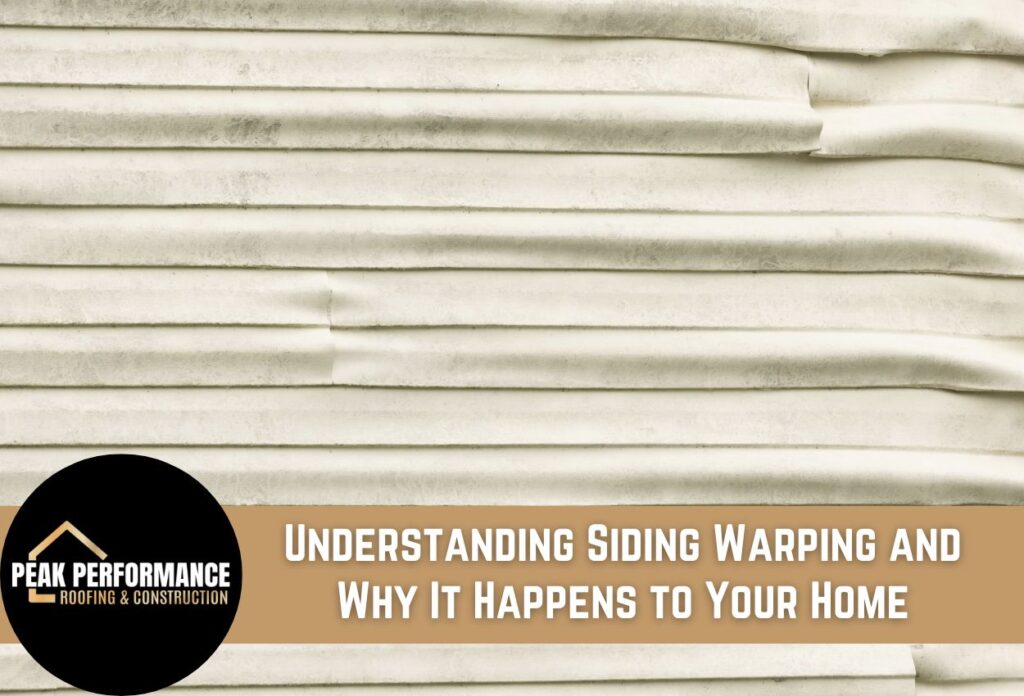

Siding warping transforms straight, uniform exterior panels into distorted surfaces that compromise both your home’s appearance and protection. This common problem occurs when exterior materials bend, bow, or buckle away from their original flat position, creating waves, curves, or ripples across the surface of your home’s exterior walls.

Siding warping can occur because of several factors that affect different materials in various ways. Heat damage to exterior siding ranks among the primary culprits, particularly during intense summer months when direct sunlight and high temperatures cause materials to expand beyond their normal limits. Moisture problems behind siding are another significant threat, as trapped water leads to swelling, rotting, and structural instability that forces panels out of alignment.

Siding installation mistakes also contribute substantially to warping issues. Improperly fastened panels, inadequate spacing for thermal expansion, or incorrect techniques create stress points that eventually manifest as visible distortion. Vinyl siding warping prevention is especially important since this popular material is more susceptible to heat-related damage compared to other options.

Recognizing warped siding early helps homeowners address underlying causes before extensive damage occurs. Understanding when to replace warped siding versus attempting repairs can save significant expense while protecting your home’s structural integrity and curb appeal.

Heat-Related Damage That Causes Siding to Buckle and Bend

Heat damage to exterior siding occurs through two primary mechanisms that create the thermal stress responsible for warping and distortion. Direct sunlight exposure combined with extreme temperatures forces siding materials to undergo thermal expansion, where panels literally grow larger as temperatures rise throughout the day.

Vinyl siding is especially vulnerable to this expansion process, and it can grow significantly when heated above normal temperatures. Dark-colored siding absorbs more solar energy, intensifying the expansion effect and increasing the likelihood of buckling. When siding expands but lacks adequate space to move freely, the material has nowhere to go except outward, creating the characteristic waves and bows associated with heat damage.

Heat reflection from windows and nearby surfaces creates concentrated hot spots that can warp siding panels in localized areas. Low-E windows, metal roofs, and reflective surfaces focus intense heat onto specific sections of siding, sometimes reaching temperatures well above what the material was designed to withstand. These reflected heat sources can cause temperatures to spike dramatically, leading to rapid thermal expansion in targeted zones.

Understanding what causes siding to warp helps homeowners identify potential heat sources around their property. Air conditioning units, grills, and other heat-generating equipment positioned too close to exterior walls can also contribute to thermal damage. Preventing warping requires maintaining proper clearances from heat sources and ensuring adequate ventilation behind siding panels to prevent heat buildup.

Installation Errors That Lead to Warped Siding Problems

Siding installation mistakes can create future warping problems when contractors fail to use the right techniques. Improper spacing represents one of the most critical errors, as siding materials require adequate room for natural thermal expansion and contraction cycles that occur with temperature changes throughout seasons.

Incorrect nailing techniques restrict this essential movement, causing panels to buckle when they attempt to expand but cannot move freely. Nails driven too tightly against siding panels prevent the natural sliding motion required during thermal cycles, while nails placed in the wrong locations create stress concentration points that eventually lead to warping. Professional installation requires nails to be positioned in designated slots with proper spacing to allow material movement.

Inadequate ventilation behind siding creates moisture problems that promote warping. Without proper airflow, trapped moisture cannot escape, leading to temperature buildup and humidity accumulation that causes materials to swell and distort. This trapped moisture also creates conditions for mold growth and material deterioration that weakens the home’s overall integrity.

Knowing what installation defects to look for means homeowners can recognize potential problems early. Poor starter strip installation, inadequate house wrap application, and improper overlap techniques all contribute to ventilation problems that eventually manifest as warped panels. Preventing warping depends heavily on correct installation practices that accommodate material properties and environmental conditions while maintaining proper moisture management.

Manufacturing Defects and Material Quality Issues

Substandard siding materials often contain inherent weaknesses that make them unable to withstand normal weather conditions and temperature changes that quality materials handle without problems. Manufacturing defects in siding production can include inconsistent material thickness, improper chemical composition, or inadequate quality control processes that result in panels with varying structural integrity across different sections.

Poor material formulation affects how siding responds to thermal expansion cycles, with inferior vinyl compounds becoming brittle in cold weather or overly flexible in heat. These inconsistencies create stress points where warping typically begins, as weaker sections cannot maintain their shape under normal environmental pressures. Low-grade materials may also lack proper UV stabilizers, causing them to break down more rapidly when exposed to sunlight.

Improper material storage and handling before installation significantly impacts long-term siding performance and contributes to premature warping problems. Siding stored in direct sunlight or extreme temperatures can develop preinstallation stress that makes panels more susceptible to future distortion. Materials stacked improperly or stored on uneven surfaces may develop permanent bends or curves that become more pronounced after installation.

Moisture exposure during storage creates additional problems when materials absorb water before installation begins. This pre-existing moisture content affects how panels respond to environmental conditions once installed, often leading to accelerated warping as materials attempt to reach equilibrium with surrounding humidity levels. Quality contractors recognize these storage-related issues and inspect materials carefully before beginning installation work.

Prevention Strategies to Protect Your Siding

Implementing effective prevention strategies protects your siding by addressing the root causes of warping before they create extensive damage. Regular maintenance practices are the first step in preventing warping, requiring homeowners to conduct consistent inspections that identify potential problems in their early stages.

Proper maintenance begins with seasonal inspections that examine panels for early signs of buckling, bowing, or discoloration that indicates heat damage. Look for loose panels, gaps between sections, or areas where caulking has failed, as these conditions often create moisture problems behind siding. Clean siding surfaces regularly using appropriate methods for your material type, removing dirt and debris that can trap heat and accelerate warping.

Choosing appropriate siding materials and colors significantly impacts long-term performance and warping resistance. Light-colored siding reflects more solar energy than dark options, reducing thermal expansion stress that leads to distortion. Consider your local climate conditions when selecting materials, as certain types perform better in high-heat environments or areas with frequent temperature fluctuations.

Understanding what causes siding to warp helps property owners make the right decisions about materials and maintenance priorities. Ensure adequate ventilation behind siding panels during installation, maintain proper clearances from heat sources like grills and air conditioning units, and address drainage issues that could create moisture accumulation. Knowing when to replace warped siding prevents minor problems from needing extensive repairs.

When Professional Siding Replacement is Necessary

Determining whether warped siding requires repair or complete replacement depends on several assessment criteria that professional contractors evaluate during thorough inspections. The extent of warping across affected panels serves as the primary indicator. Minor buckling is often addressable through targeted repairs, while extensive distortion typically necessitates full panel replacement.

A structural integrity assessment reveals whether underlying damage exists beyond surface-level warping issues. When moisture problems have compromised the building or created rot in structural components, simple panel replacement may not address the root cause. Professionals examine the condition of house wrap, insulation, and framing materials to determine the scope of necessary work.

Age and material condition significantly influence replacement decisions, particularly when dealing with older siding systems that may contain outdated materials or installation techniques. Multiple warped sections across different areas of the home often indicate systemic problems with the original installation or material quality that make spot repairs ineffective as long-term solutions.

Selecting qualified contractors requires verifying their licensing, insurance coverage, and experience with your specific siding material type. Make sure the work proposed addresses the underlying causes of warping rather than just cosmetic fixes. Professional siding replacement should include moisture barrier updates, proper ventilation installation, and adherence to current building codes. Understanding when to replace warped siding helps homeowners avoid repeated problems while ensuring their investment provides lasting protection and improved curb appeal for years ahead.

Protect Your Home with Peak Performance Roofing & Construction

If you’ve noticed warping or other damage to your home’s siding, it’s important to take care of it as soon as possible to prevent further deterioration and potential structural problems. Understanding what causes siding to warp is the first step in protecting your investment. Whether it’s due to heat damage, moisture issues, installation errors, or material defects, taking action can save you from expensive repairs in the future.

Don’t let siding problems compromise the safety and aesthetics of your home. Call Peak Performance Roofing & Construction today at (918) 694-1483 for a comprehensive inspection and expert siding replacement services.