A Guide to PVC Roofing Membrane Installation for Commercial Buildings

Key Points:

- Proper surface preparation and specialized equipment are essential for successful installation and long-term performance.

- Professional installation requires precise fastener spacing and temperature control during welding to prevent common failure points.

- Post-installation inspections and regular maintenance maximize membrane lifespan and preserve manufacturer warranty coverage.

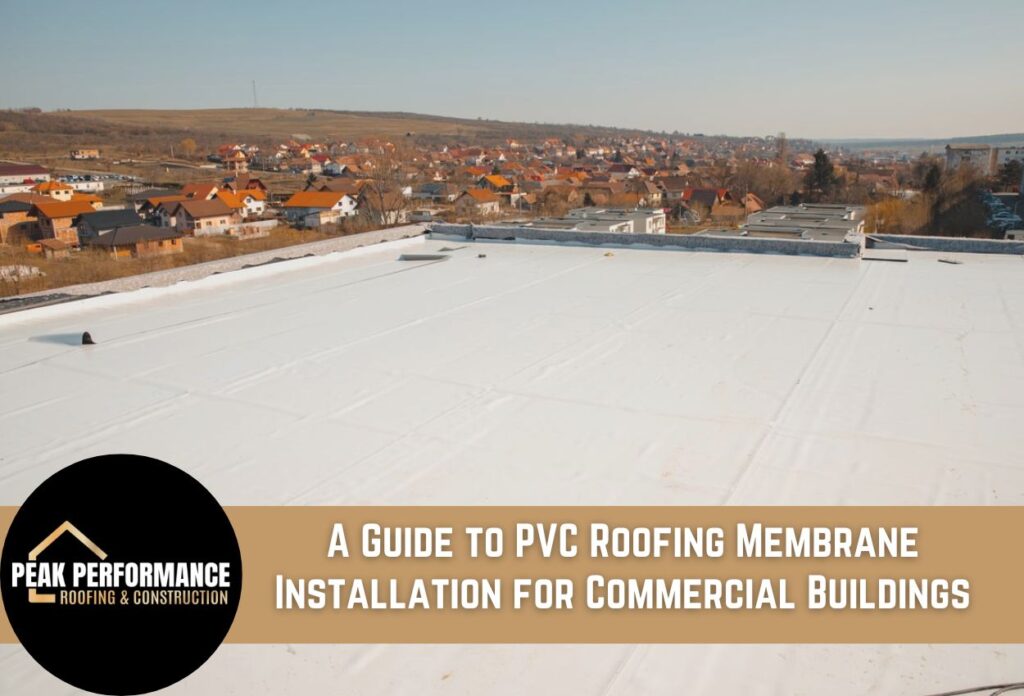

PVC roofing membranes have become a top choice for commercial buildings across different climates due to their exceptional durability and performance characteristics. These single-ply roofing systems offer superior resistance to chemicals, fire, and extreme weather conditions while providing excellent energy efficiency through their reflective white surface.

The PVC roofing membrane installation process requires specific techniques and attention to detail to achieve the best results. Unlike traditional roofing materials, PVC membranes create a seamless barrier when properly installed using heat-welded seams that form watertight bonds stronger than the membrane itself. This advanced PVC membrane roofing technique eliminates common leak points found in other roofing systems.

Commercial membrane attachment methods vary depending on building structure and local building codes, but all successful installations share common preparation and application principles. Property owners who invest in proper PVC roof seam methods and professional installation typically see significant long-term benefits, including reduced energy costs, minimal maintenance requirements, and an extended lifespan of the roof.

Essential Tools and Materials Needed Before Starting Installation

Successful PVC roofing membrane installation requires specialized equipment that differs significantly from traditional roofing tools. Professional contractors rely on hot-air welding machines to create the heat-sealed bonds essential for PVC membrane roofing techniques. These welding units must maintain consistent temperatures between 800 to 1,000 degrees Fahrenheit to achieve proper seam fusion without damaging the membrane material.

Cutting instruments specifically designed for single-ply roof installation include sharp utility knives with replaceable blades, membrane shears, and precision measuring tools. Safety equipment remains critical throughout the commercial roof membrane attachment process, requiring non-slip footwear, harnesses, and protective eyewear when operating welding equipment.

Material selection directly impacts installation success and long-term performance. High-quality PVC membranes typically feature reinforced polyester scrims that provide dimensional stability during temperature fluctuations. Compatible insulation materials must complement the PVC system while meeting local energy codes and structural requirements.

Additional essential supplies include seam probes for testing weld quality, rollers for pressure application during PVC roof seam methods, and appropriate fasteners rated for the specific deck type. Membrane primers and cleaners ensure proper adhesion at critical connection points. Professional contractors also stock repair patches and additional membrane sections to address any installation adjustments needed during the application process.

Roof Surface Preparation and Assessment Requirements

Proper roof surface preparation forms the foundation for a successful PVC roofing membrane installation. The existing roof deck must undergo thorough cleaning to remove all debris, loose materials, and contaminants that could compromise the membrane’s adhesion. Power washing or mechanical cleaning removes accumulated dirt, while scraping eliminates old adhesive residues and coating materials that interfere with new membrane bonding.

Contractors examine deck surfaces for proper slope, ensuring adequate drainage away from critical areas. Damaged or deteriorated decking sections require replacement or reinforcement to provide stable roof deck conditions. Fastener patterns receive inspection to confirm adequate attachment points for commercial roof membrane attachment systems.

Moisture detection plays an important role in preparation since trapped moisture causes membrane failure and compromises single-ply roof installation integrity. Electronic moisture meters locate wet insulation or deck areas that need drying time before membrane application. Areas with persistent moisture problems may require vapor barriers or modified installation techniques to prevent future complications.

Surface irregularities are filled, sanded, and leveled with compounds to create smooth transitions for the placement of the membrane. Proper preparation eliminates sharp edges, protruding fasteners, and surface variations that could puncture or stress the PVC membrane. Testing the roof deck’s compatibility ensures chemical interactions won’t affect the PVC roof seam or long-term membrane performance once installation begins.

Professional Installation Techniques and Best Practices

Professional contractors utilize specific fastener patterns designed to distribute wind loads evenly across the surface of the membrane while preventing concentrated points of stress that could lead to premature failure. The attachment system begins with securing the membrane along perimeter edges using appropriate fasteners spaced according to manufacturer specifications and local wind load requirements.

Proper membrane positioning requires a close look at the expansion and contraction from freeze-thaw cycles during single-ply roof installation. PVC membranes expand and contract with temperature changes, making proper positioning critical for long-term performance. Contractors position membrane sheets with adequate overlap zones while maintaining consistent alignment across the entire roof surface. This positioning prevents wrinkles and ensures uniform stress distribution during thermal cycling.

Critical spacing requirements vary based on roof height, geographic location, and building exposure conditions. Commercial roof membrane attachment typically requires fastener spacing between 6 to 12 inches on center along seam edges, with closer spacing in high-wind zones. Interior field fasteners follow predetermined patterns that account for membrane thickness and the type of material used for the roof deck. Professional installers use laser measurements and chalk lines to maintain consistent spacing patterns that meet engineering specifications.

Wind resistance depends heavily on proper fastener selection and installation depth. PVC membrane roofing techniques incorporate corrosion-resistant fasteners with appropriate length and thread design for the specific deck material. Each fastener must achieve proper embedment without over-driving, which could compromise membrane integrity through the PVC roof seam.

Heat Welding and Seam Creation Methods

Professional heat welding forms the cornerstone of successful PVC roofing membrane installation process applications, creating bonds that exceed the strength of the base membrane material. Hot-air welding machines operate at precise temperatures between 800 and 1,000 degrees to fuse adjacent membrane sheets through controlled heat application and pressure rolling. This PVC membrane roofing technique produces watertight seams that eliminate potential leak pathways common in mechanically fastened systems.

Welding equipment requires careful calibration before beginning seam creation to ensure consistent temperature control throughout the installation. Professional contractors adjust welding speed and temperature settings based on ambient conditions, membrane thickness, and roof deck temperature variations. The welding process involves overlapping membrane edges by approximately 3 inches, applying controlled heat while simultaneously using pressure rollers to create uniform fusion across the entire seam width.

Quality control testing procedures verify seam integrity immediately following completion of each welded section during single-ply roof installation. Seam probes test bond strength by attempting to separate welded areas using controlled pressure. Any sections showing inadequate fusion require immediate re-welding before continuing with adjacent areas. Commercial roof membrane attachment standards mandate testing protocols that include both destructive and non-destructive evaluation methods to identify potential weak points.

Temperature monitoring throughout the welding process prevents overheating damage while ensuring adequate fusion temperatures.

Common Installation Mistakes and How to Avoid Them

Installation errors during the PVC roof membrane installation process can significantly impact system performance and longevity. Insufficient overlap reduces seam strength and creates vulnerable areas where wind uplift forces can separate membrane sections. Professional installers prevent this issue by using measurement guides and marking systems that ensure uniform overlap dimensions across all seam locations.

Temperature-related installation problems compromise PVC membrane roofing techniques when contractors attempt welding during unsuitable weather conditions. Welding operations conducted in temperatures below 40 degrees or during high humidity often produce weak seam bonds that fail prematurely. Additionally, attempting single-ply roof installation during windy conditions prevents proper membrane control and leads to wrinkled or improperly positioned sections that require expensive repairs.

Surface contamination issues arise when cleaning procedures prove inadequate before beginning commercial roof membrane attachment. Dust, moisture, or chemical residues on membrane surfaces prevent proper heat welding and create bond failures at critical seam locations. Experienced contractors maintain strict cleaning protocols and perform surface preparation verification before welding operations commence.

Fastener installation errors occur when contractors use incorrect fastener types, improper spacing patterns, or inadequate drive depths. These mistakes reduce wind resistance capacity and create stress concentration points that lead to membrane tearing during weather. Proper PVC roof seams require systematic fastener verification and adherence to manufacturer specifications throughout the installation process.

Post-Installation Inspection and Maintenance Guidelines

Inspection immediately following PVC roofing membrane installation process completion ensures all system components meet performance specifications. Professional contractors conduct systematic evaluations that examine seam quality, fastener placement, and membrane surface conditions across the entire roof. These inspections identify any areas requiring immediate attention before weather exposure occurs, preventing minor issues from developing into expensive repairs.

Testing protocols verify the integrity of PVC membrane roofing techniques through both visual examination and physical testing methods. Seam probing confirms adequate weld strength along all connection points, while a surface inspection of the membrane identifies punctures, wrinkles, or contamination that could affect performance. Contractors document inspection findings with photographic evidence and detailed reports that establish baseline conditions for future maintenance planning.

Scheduled maintenance programs maximize membrane lifespan and preserve manufacturer warranty coverage through preventive care protocols. Regular cleaning removes debris and contaminants that accelerate membrane degradation, while periodic inspections identify developing problems before they compromise system integrity. Professional maintenance includes drain cleaning, seam monitoring, and surface treatment applications that maintain optimal single-ply roof installation performance.

Commercial roof membrane attachment points require ongoing attention since thermal cycling and building movement create stress at connection locations. Annual professional inspections evaluate fastener conditions, membrane expansion joint performance, and perimeter attachment integrity. Maintenance should address manufacturer requirements while providing early detection of issues that could void warranty coverage or compromise the long-term PVC roof seam throughout the system’s service life.

Trust Peak Performance Roofing & Construction for Your PVC Roofing Needs

If you’re considering a PVC roof membrane installation for your commercial building, ensuring that the job is done right is crucial for longevity and performance. Peak Performance Roofing & Construction specializes in professional PVC membrane roofing techniques, ensuring that every phase from initial assessment to post-installation inspection is handled with expert care. Our team is equipped with the necessary tools and knowledge to avoid common installation mistakes and to execute the perfect single-ply roof installation.

Call Peak Performance Roofing & Construction today at (918) 694-1483 to discuss your roofing project and schedule a consultation. Let us help you maximize the lifespan and efficiency of your commercial roofing system.