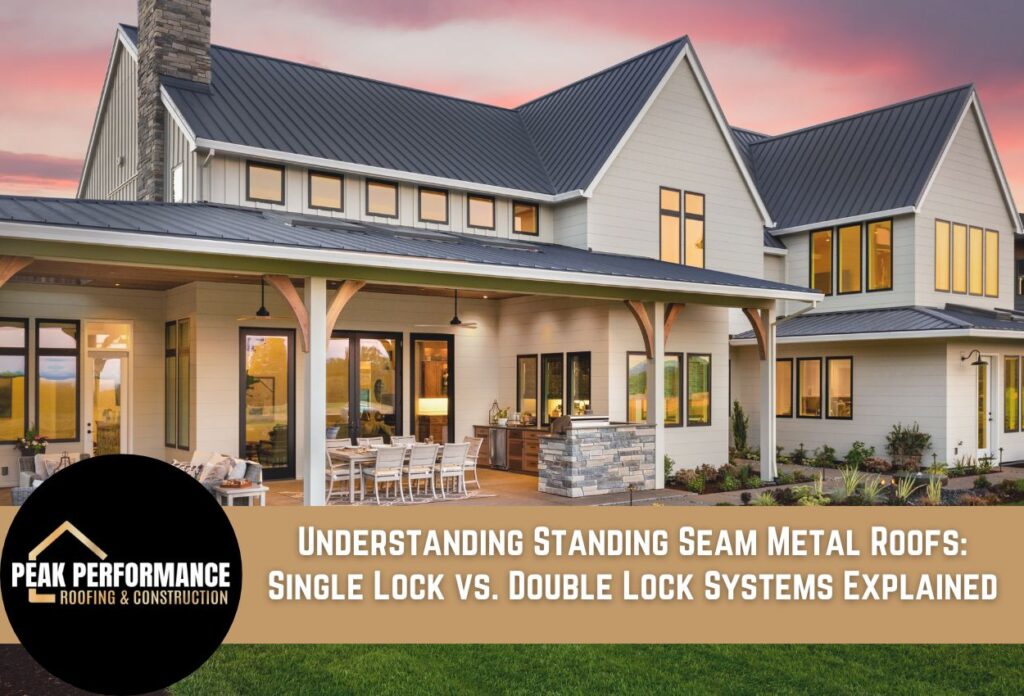

Understanding Standing Seam Metal Roofs: Single Lock vs. Double Lock Systems Explained

Standing seam metal roof systems are one of the most durable and weather-resistant roofing solutions available today. The distinguishing feature of these systems is their raised seams that connect adjacent metal panels, creating a continuous barrier against water infiltration. The locking mechanism used to join these panels determines the overall performance, longevity, and structural integrity of the entire roofing system.

Two primary seaming methods dominate the standing seam roof market: single lock and double lock systems. Each approach has advantages and limitations that impact installation requirements, weather resistance, and long-term durability. Single lock systems utilize one fold to connect metal roof panels, while double lock systems have two mechanical folds for enhanced security.

The choice between single lock and double lock installation affects everything from project complexity to the roof’s ability to withstand extreme weather conditions. Understanding the benefits of each option is essential for property owners, contractors, and architects when selecting the appropriate mechanical seam roofing installation method for specific projects.

How Single Lock Standing Seam Systems Work

Single lock standing seam systems are installed through a streamlined seaming process that creates one mechanical fold between adjacent metal panels. The seaming process involves positioning two panel edges together and using specialized equipment to bend and compress the metal into a secure interlocking connection. This creates a raised seam that stands vertically above the roof surface, allowing water to flow around rather than through the panel joints.

The characteristics of single lock panels typically feature seam heights ranging from one to two inches, with standard panel widths between 12 and 24 inches. These metal roofing panel connections rely on clips or fasteners that attach to the roof deck beneath the seam, creating a concealed fastening system that eliminates exposed screws on the roof surface.

The standing seams allow panels to move independently while maintaining watertight connections. This mechanical seam roofing installation process requires fewer seaming passes compared to double lock alternatives, reducing installation time while maintaining structural integrity. Standing seam roofing projects with limited project timelines benefit from the simplified connections that single lock systems provide.

The Engineering Behind Double Lock Standing Seam Systems

Double lock standing seam systems utilize an advanced seaming process that creates two distinct mechanical folds between adjacent metal panels. This enhanced mechanical connection begins with positioning panel edges together, followed by specialized seaming equipment making two separate passes to form the complete joint. The first fold creates an initial connection, while the second fold compresses and locks the seam into its final configuration, resulting in superior seam integrity.

The double fold seaming process generates increased seam rigidity compared to single lock alternatives. This enhanced structural performance stems from the additional material compression and the geometric strength created by the dual-fold configuration. The design provides twice the protection over the fasteners, reducing the likelihood of seam failure under extreme weather conditions or thermal cycling.

Commercial standing seam roofing systems generally benefit from the improved leak resistance of double lock configurations. The structural advantages extend to increased wind uplift resistance, with double lock seams generally withstanding higher uplift forces than single lock options.

These standing seam metal roof systems also demonstrate enhanced thermal performance by better accommoding metal roofing panel connections during expansion and contraction, contributing to long-term system durability and reduced maintenance requirements.

Weather Resistance and Durability: Direct Comparison

The performance differences between single lock and double lock standing seam metal roof systems are clear when analyzing their resistance to challenging weather conditions. Double lock systems demonstrate superior wind uplift resistance due to their enhanced mechanical connection strength. The dual-fold seaming process creates increased structural rigidity that better withstands high winds.

Thermal expansion accommodation varies significantly between these mechanical seam roofing installation methods. Double lock systems are typically more stable during temperature fluctuations due to their enhanced seam strength and reduced panel movement at connection points. Single lock systems, while still effective, allow slightly more thermal movement that can lead to increased stress on metal roofing panel connections over time.

Long-term durability favors double lock standing seam systems for their enhanced structural integrity and fewer maintenance needs. Standing seam roofs using double lock technology typically have service lives extending decades with minimal seam-related issues. Single lock systems generally provide reliable performance for similar amounts of time, though they may require periodic seam inspection and potential reseaming in high-stress areas. Overall, both systems effectively handle severe weather conditions and are robust options, but double lock panels offer superior performance for areas with extreme weather.

Installation Requirements and Contractor Considerations

Single lock and double lock standing seam installations differ significantly in complexity and specialization. Single lock systems require standard portable seaming machines that complete the connection in one pass, making them more accessible for contractors with basic mechanical seaming equipment. Double lock systems need more sophisticated seaming machinery capable of precise two-pass operations, often requiring specialized equipment that is a substantial investment for roofing contractors.

Skill level requirements also vary between these metal panel connection methods. Single lock installation typically requires moderate technical expertise, allowing experienced roofers to achieve proficiency within a reasonable training period. Double lock systems need advanced technical skills and extensive training due to the precision required for proper dual-fold seaming.

How long installation takes for both options significantly impact project scheduling and labor costs. Single lock standing seam metal roof systems generally install faster than double lock alternatives due to the simplified seaming process. Double lock standing seam roofing projects require additional time for the two-pass seaming operation and increased quality control measures. These timing considerations directly influence overall installation efficiency, making single lock systems attractive for time-sensitive projects while double lock systems better suit applications prioritizing maximum performance and longevity.

Ideal Applications: When to Choose Each System

While both single and double lock methods have advantages, commercial and industrial building applications typically benefit most from double lock standing seam systems due to their enhanced performance. High-rise buildings, manufacturing facilities, and institutional structures require the maximum wind uplift resistance and weather protection that double lock roof installations provide. These commercial standing seam roofing applications often face stringent building codes that require specific performance ratings that double lock systems readily meet or exceed.

Industrial environments with exposure to extreme weather, chemicals, or high-traffic areas benefit from the enhanced durability of double lock metal roofing panel connections. Warehouses, airports, and large retail facilities represent ideal candidates for this technology due to their size, exposure levels, and long-term performance requirements. The initial investment in double lock standing seam metal roof systems is often seen as cost-effective over the extended service life these roofs provide.

Residential applications often find single lock systems provide optimal balance between performance and practicality. Single-family homes, townhomes, and smaller commercial buildings with slopes exceeding 3:12 typically achieve adequate weather protection through single lock installation. These applications benefit from faster installation times, reduced complexity, and lower equipment requirements while maintaining reliable long-term performance. Low-slope residential projects particularly suit single lock systems where installation accessibility and cost considerations take priority over maximum performance specifications, though both systems provide excellent weather resistance for typical residential applications.

Making the Right Choice for Your Tulsa Roofing Project

Selecting between single lock and double lock standing seam metal roof systems requires looking at multiple project-specific factors. Building type serves as a primary consideration, with commercial structures typically needing the enhanced performance of double lock systems, while residential applications often find single lock solutions provide adequate protection. The intended building use, occupancy requirements, and structural loads all influence which mechanical seam roofing installation method delivers the best results.

Additionally, Oklahoma’s climate, which includes severe thunderstorms, hail, and extreme temperature variations, should directly impact which system is chosen. Double lock standing seam roofing systems excel in areas prone to severe weather due to their superior structural integrity. Properties in tornado-prone zones particularly benefit from the enhanced wind resistance that these metal roofing panel connections provide.

Long-term performance expectations significantly influence the decision between these seam options. Properties requiring maximum longevity and minimal maintenance typically favor double lock systems despite higher initial investment. Buildings with shorter service life expectations or budget constraints may find single lock standing seam metal roof systems provide adequate performance at reduced costs. The expected building lifecycle, maintenance capabilities, and performance requirements help determine which system delivers the best value over time.

Consulting a professional is especially crucial when navigating this important decision. Qualified metal roofing contractors have the technical expertise to evaluate site-specific conditions, building requirements, and local building code, ensuring the long-term performance of your new standing seam metal roof system.

Unlock the Best Roofing Solution with Peak Performance Roofing & Construction

Deciding between single lock vs. double lock standing seam roofing systems can be complex, especially when considering the harsh weather conditions in Oklahoma. Understanding their differences is crucial for your property’s protection and longevity. Whether it’s enhanced durability against severe weather with double lock systems or the cost-effectiveness and sufficient protection offered by single lock systems, making the right choice matters.

If you’re planning a roofing project in Tulsa and need expert guidance to navigate these choices, don’t hesitate to contact Peak Performance Roofing & Construction. Our seasoned professionals are here to help you select the ideal metal roofing system that aligns with your property’s requirements and the local climate.

Ready to transform your property with a reliable roofing solution? Call us at (918) 694-1483 and ensure your roof is built to last!